10. June, 2025delish0

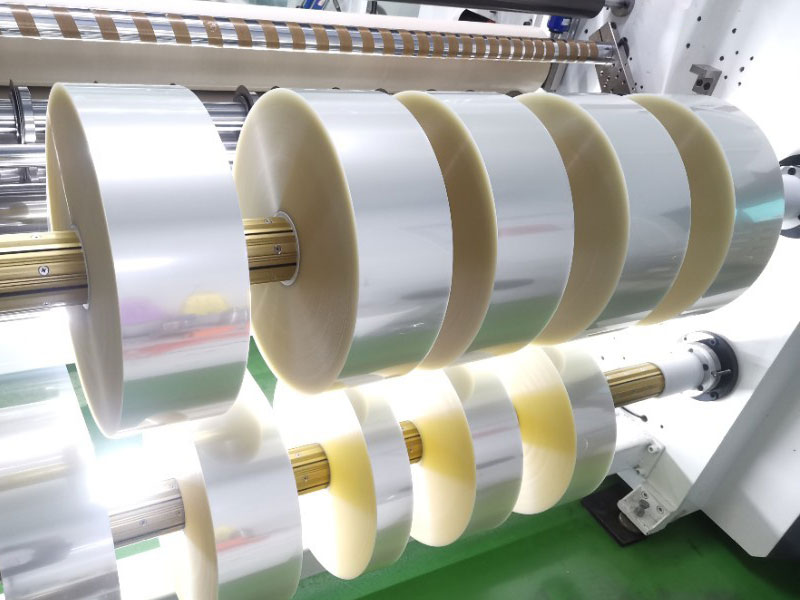

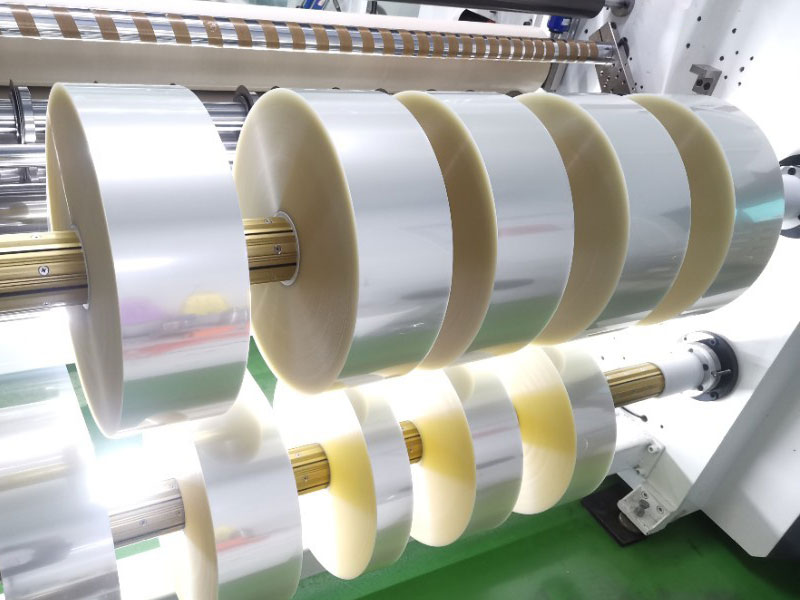

Capacitor film slitting machine plays a key role in the new energy industry, especially in the manufacture of lithium battery separators, and its high-precision slitting technology directly affects the quality of the separator and the performance of the battery. The following is the detailed technical scheme and application analysis of lithium battery separator slitting:

1. Special requirements for lithium battery separator slitting

1. Processing of extremely thin materials

The thickness of the diaphragm is usually 5-20 μm (micron), and the slitter needs to have ultra-high-precision tension control (within ±0.5%) and micron-level cutting accuracy.

2. Pollution-free slitting

The diaphragm is sensitive to dust and metal chips, and the slitting machine needs to be equipped with dust-free environment design and anti-static device.

3. Low thermal impact

To avoid shrinkage or deformation of the diaphragm caused by friction and heat during the slitting process, low-temperature blades or laser slitting are required.

4. Edge quality

The cut edge must be smooth and burr-free to prevent the burr from piercing the separator and causing a short circuit in the battery.

2. Key technology adaptation scheme of capacitor film slitting machine

1. Slitting method selection

• Mechanical blade slitting

◦ Applicable material: PP/PE base diaphragm.

◦ Technical Points:

▪ Use tungsten carbide or ceramic inserts (hardness≥ HRA90).

▪ The blade angle is 25°-35° to reduce cutting resistance.

▪ With air suspension guide rollers to reduce contact friction.

• Laser slitting

◦ Applicable materials: ceramic-coated separators, PI and other high-strength films.

◦ Technical Points:

▪ Ultraviolet laser (wavelength 355nm) can achieve < 10 μm heat-affected zone.

▪ The spot positioning accuracy is ± 2μm, and the speed can reach 300m/min.

2. Core subsystem configuration

• Tension control

◦ Closed-loop PID control + multi-stage tension zone (unwinding→ traction → winding), and the fluctuation is controlled at ±0.3N.

◦ Equipped with ultrasonic or laser thickness gauge for real-time feedback adjustment.

• Web guiding system

◦ CCD vision correction (accuracy±0.1mm), suitable for diaphragms with a width of 800-1500mm.

• Dust removal design

◦ Ionizing air knife + HEPA filtration (cleanliness ISO Class 5).

3. Winding technology

• Constant linear speed winding (error < 0.1%), driven by servo motor.

• Surface take-up (contact) vs. center take-up (non-contact), the latter is more suitable for ultra-thin diaphragms.

3. Application cases in the new energy industry

1. Wet diaphragm slitting

◦ Material: PE base film (thickness 9 μm).

◦ Device parameters:

▪ Slitting speed: 150m/min

▪ Slitting width: 650±0.2mm

▪ Burr Height: < 3 μm (SEM detection).

2. Coated diaphragm processing

◦ Challenge: The ceramic coating is easy to peel off.

◦ Solution: laser slitting + negative pressure chip adsorption system.

Fourth, industry technology trends

1. Compound slitting technology

Mechanical knife + laser synchronous slitting, taking into account efficiency and quality (such as mechanical rough cutting and laser finishing first).

2. Intelligent upgrade

◦ AI defect detection (real-time identification of holes/scratches ≥ 5μm)

◦ Digital twin simulation optimizes slitting parameters.

3. Broad-based development

The new generation of slitting machine supports 2.5m width diaphragm, increasing production capacity by more than 30%.

5. Selection suggestions

• High-end market: Laser slitting models (such as Kataoka in Japan and Atlas in Germany) are preferred.

• Cost-sensitive scenarios: domestic high-precision mechanical slitting machines (such as Shenzhen Xinyu and Dongguan Hengli).

Through customized slitting solutions, the capacitor film slitting machine can significantly improve the yield rate of lithium battery separators (up to more than 99.5%), meeting the demand for high-performance battery materials in the new energy industry.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter