27. June, 2025delish0

Selection guide for slitting machines for different materials

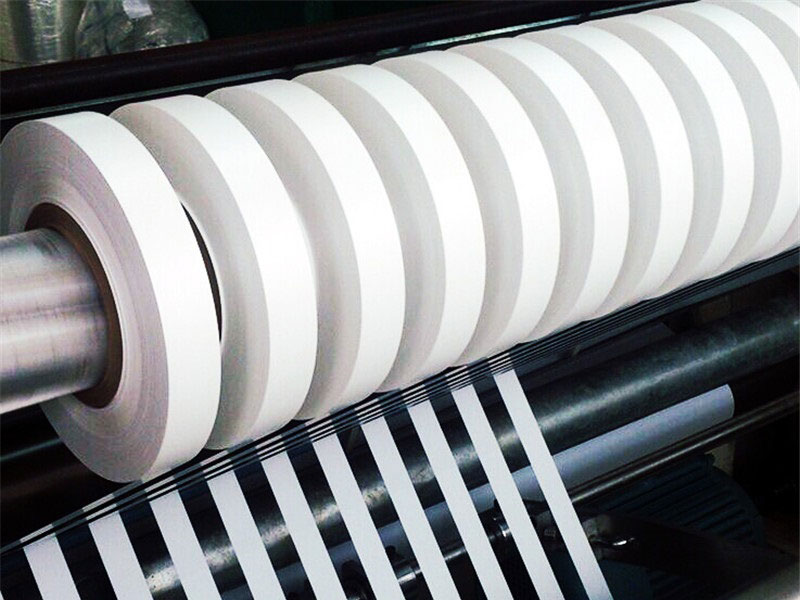

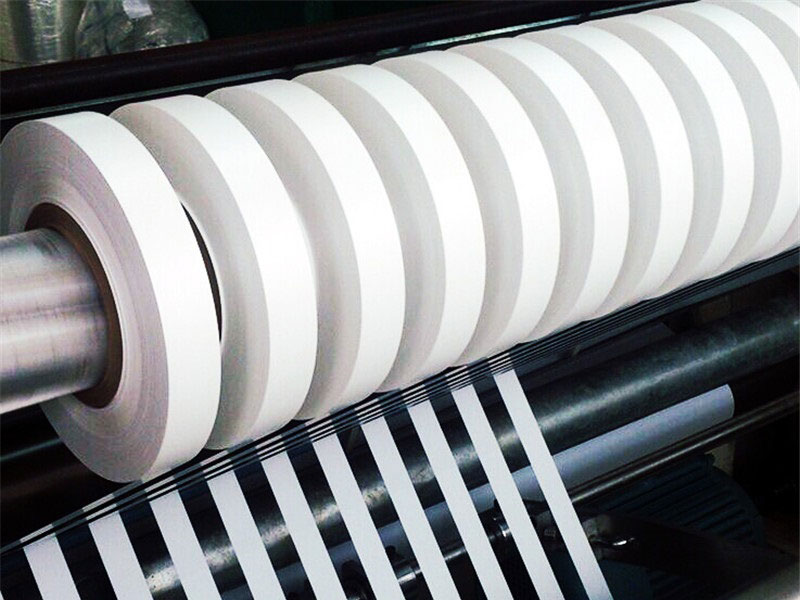

Selection of film material slitting machine

Applicable models:

• Cantilever slitting machine (for thin films)

• Twin shaft slitting machine (suitable for thicker or laminated films)

• Round knife slitting machine (high precision required)

Key Considerations:

• Tension control system (high accuracy required)

• Static Eliminator

• Edge uniformity requirements

• Slitting speed (typically 50-800 m/min)

• Winding method (center or surface winding)

Selection of paper material slitting machine

Applicable models:

• Flat knife slitting machine (plain paper)

• Air knife slitting machine (high-grade paper products)

• Combined slitting machine (cardboard, cardboard)

Key Considerations:

• Dust collection system

• Tool wear resistance

• Slitting thickness range (from tissue to cardboard)

• Anti-wrinkle device

• Slitting speed (usually 30-300 m/min)

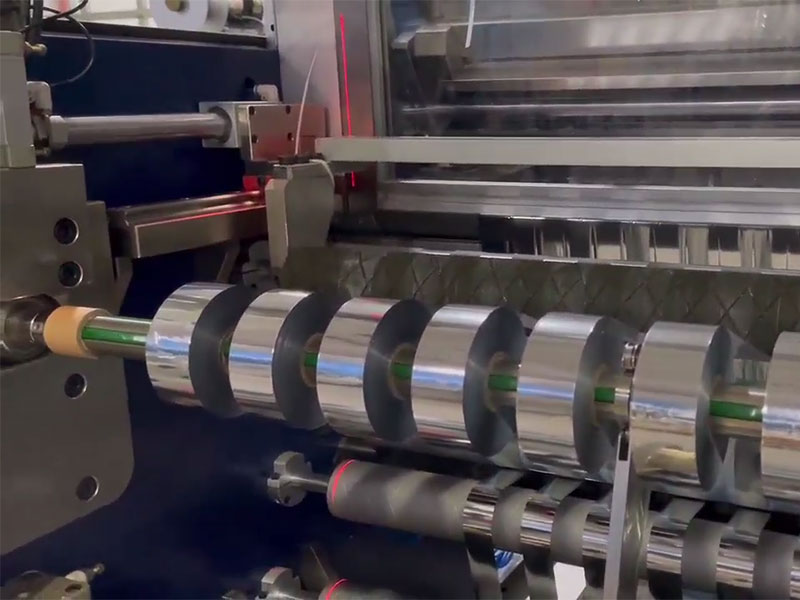

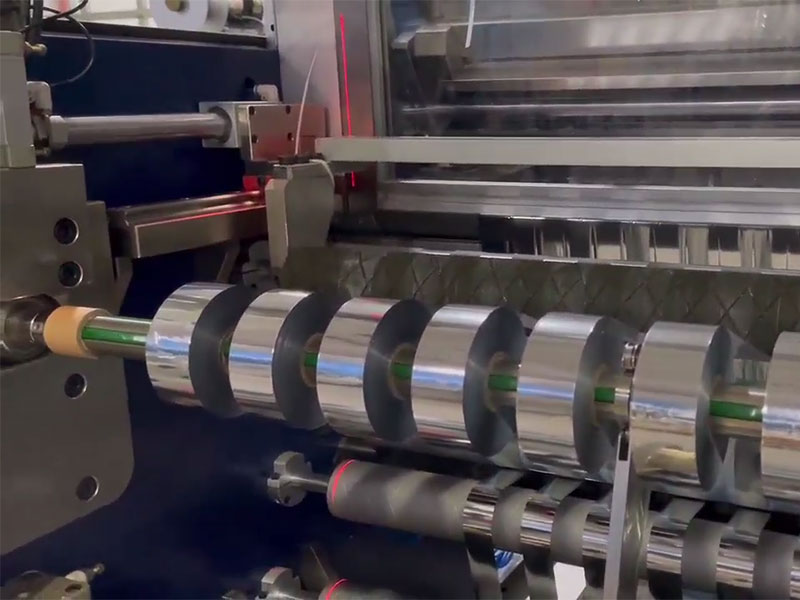

Selection of metal foil slitting machine

Applicable models:

• Heavy-duty precision slitting machine

• Hydraulic slitting machine

• High rigidity twin-shaft slitting machine

Key Considerations:

• High rigidity requirements for equipment

• Special alloy tools

• High-precision tension control (±1%)

• Edge burr control

• Slitting speed (usually 5-150 m/min)

• Lubricating oil/cooling system

General selection principle

1. Material properties: thickness, hardness, ductility, surface properties

2. Accuracy requirements: slitting width tolerance, edge quality

3. Production volume: Determine the degree and speed of equipment automation

4. Follow-up process: whether on-line inspection or special winding method is required

5. Budget: There is a large price difference from semi-automatic to fully automatic CNC equipment

It is recommended to test cut the material before the final selection to ensure that the performance of the equipment meets the actual production needs.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter