01. August, 2025delish0

The three core advantages and specific implementation methods of paper cutting tube cutting machines to improve production efficiency are as follows, combined with automation, precise control and process optimization, which can significantly increase production capacity:

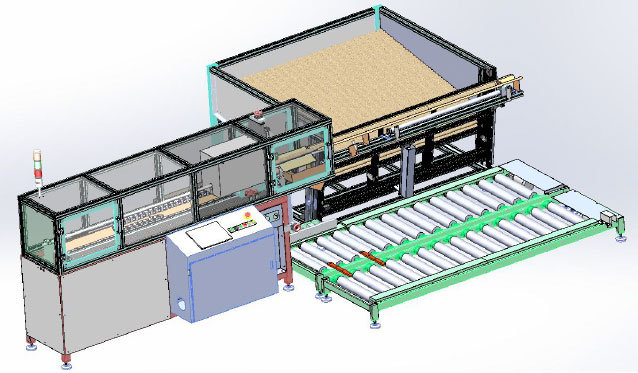

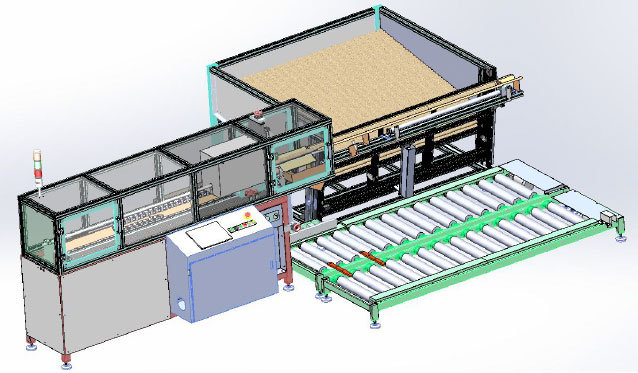

1. Automation upgrade – reduce manual intervention and continuous operation

• Advantages: Automatic feeding, cutting, and sorting integration, reducing manual operation time and realizing 24-hour continuous production.

• Implementation method:

◦ PLC control system + servo motor drive to realize automatic adjustment of feeding length and cutting speed.

◦ Automatic finished product sorting with robotic arms or conveyor belts reduces downtime.

◦ Case: After a packaging plant adopted a fully automatic paper tube cutting machine, the production capacity increased from 800 to 2,500 pieces per day, and the labor cost was reduced by 60%.

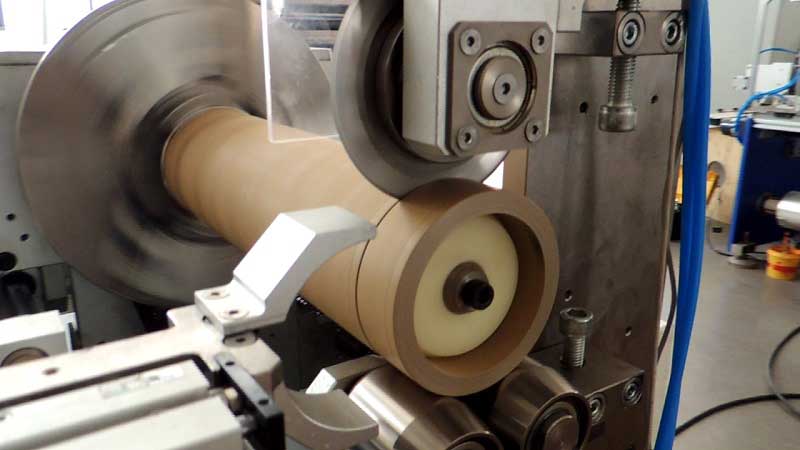

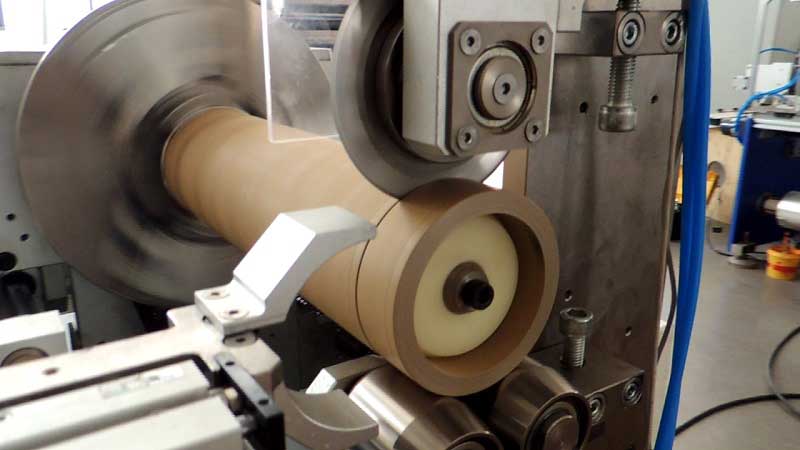

2. High-precision cutting technology - reduce scrap rate and improve material utilization

• Advantages: Laser or CNC knife die cutting accuracy reaches ±0.1mm, avoiding repeated processing and material waste.

• Implementation method:

◦ Use a high-resolution encoder to calibrate the cutting position in real time to ensure that the cut is flat and burr-free.

◦ Equipped with a vision inspection system to automatically identify and reject paper tube defects.

◦ Data comparison: The scrap rate of traditional equipment is about 5%, and it can be reduced to less than 0.5% after upgrade.

3. Multi-functional and fast switching – adapt to multi-specification orders and reduce debugging time

• Advantage: Through the modular design, the switching of paper tubes of different diameters/lengths can be completed in 3 minutes.

• Implementation method:

◦ Quick-change fixtures and a database of preset parameters (e.g., 100 specifications are stored).

◦ Train operators to switch modes with one touch on the touch screen to avoid manual adjustment errors.

◦ Actual effect: When an enterprise processes multiple batches of small orders, the equipment utilization rate increases from 50% to 85%.

Additional efficiency measures

• Preventive maintenance: Regularly lubricate the guide rails and replace tools to reduce sudden failures.

• Energy-saving design: Optional frequency conversion motor, standby power consumption is reduced by 30%.

• Data networking: Monitor production efficiency through MES systems and optimize production schedules in real time.

Through the above technical improvements, the comprehensive efficiency of the paper tube cutting machine can be increased by 40%~70%, especially suitable for large-scale production scenarios such as paper tubes, paper cores, and textile tubes. It is recommended to choose the degree of automation and precision configuration according to actual needs, balancing the input-output ratio.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter