08. August, 2025delish0

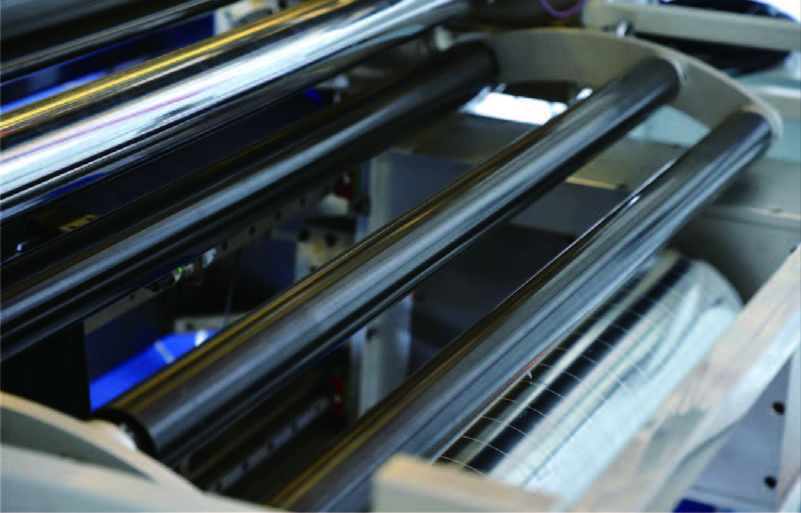

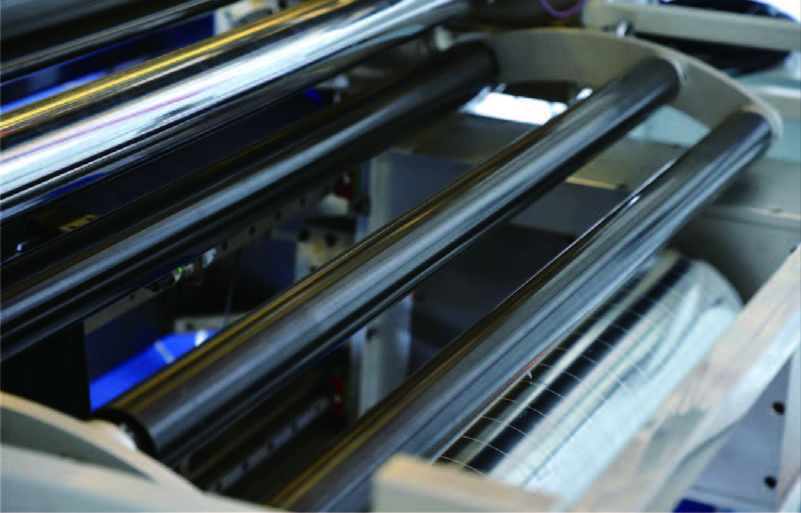

High-end solar film brands rely on slitting machines, especially high-precision slitting equipment, and the core reason is the particularity of solar film products and the strict quality requirements of the high-end market. The following analyzes this phenomenon from three dimensions: technology, market and process:

First, technical dimension: precision directly determines product performance

1. Guarantee of optical performance

High-end solar films (such as automotive thermal insulation films and building energy-saving films) need to have extremely high light transmission uniformity and no distortion. The accuracy of the slitting machine (± 0.1mm or more) ensures that the edges of the film are flat and avoid light scattering or perspective distortion caused by cutting burrs or wavy edges.

2. Integrity of multi-layer composite structures

Modern solar films are mostly 5-15 layers of nanocomposite structures (such as magnetron sputtering films). Low-precision slitting can lead to delamination or damage to the metal coating, directly affecting the thermal insulation rate (IRR) and UV rejection. For example, 3M's top-of-the-line insulation film requires a coating error of <0.05mm after slitting.

3. The need for automated correction systems

The high-end slitting machine is equipped with a laser or CCD real-time correction system, which can dynamically adjust the position of the film roll. Taking LLumar's production line as an example, its slitting machine can still maintain a deviation control of ±0.03mm at a speed of 300 m/min to avoid material waste.

Second, market dimension: balance between cost and brand premium

1. The cost of raw materials is extremely high

High-end solar film substrates (such as PET polyester) and functional coatings (ceramic particles, silver ions) can cost 5-10 times more than ordinary films. Precision slitting controls the scrap rate below 1% (manual slitting can reach 15%), directly reducing production costs.

2. Customized demand-driven

Luxury car brands (such as Mercedes-Benz and Tesla) require the sun film to fit perfectly with the curvature of the window, and the slitting machine can achieve special-shaped cutting (such as arc and diamond) through CAD data to meet the OEM order needs of OEMs.

Third, craft dimension: traditional means cannot be replaced

1. Dust-free environment requirements

Solar film slitting needs to be carried out in a Class 1000 clean room, and manual slitting can easily introduce dust, resulting in bubbles or defects in the finished product. Slitting machines from well-known brands such as V-KOOL have integrated ionic air dust removal systems.

2. Limits of tension control

The slitting tension of the solar film needs to be stable at 2-10N (about 200-1000g force), too high will stretch the film layer to change the optical parameters, and too low will cause wrinkles. The high-end slitting machine adopts magnetic powder clutch + PID closed-loop control, with an accuracy of 0.1N.

3. Microscopic effects of edge quality

Electron microscopy showed that the edge roughness (Ra) of the solar film for precision slitting was < 0.2 μm, while ordinary slitting may be > 1 μm. This difference can affect the glue flow and long-term weather resistance when applying.

Industry data to support it

• Comparison of equipment investment: The price of an imported slitting line (such as Germany's Kampf) exceeds 20 million yuan, but the yield rate can be increased to 99.5%, while the yield rate of domestic ordinary equipment is about 92%.

• Market feedback: ACE (Window Film Association) tests show that the 5-year performance degradation rate of solar film products using precision slitting is <3%, while the attenuation rate of low-precision slitting products is 8-12%.

conclusion

The reliance of high-end solar film brands on slitting machines is essentially a reflection of technical barriers. Under the requirements of hard indicators such as nanoscale functional coatings, composite structures, and optical properties, only ultra-high-precision slitting equipment can meet the needs of quality, efficiency and cost control at the same time. This logic of "precision determines quality" also explains why the leading brands in the solar film industry (such as quantum membranes and Saint-Gobain) continue to invest in the research and development and upgrading of slitting technology.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter