06. January, 2024delish0

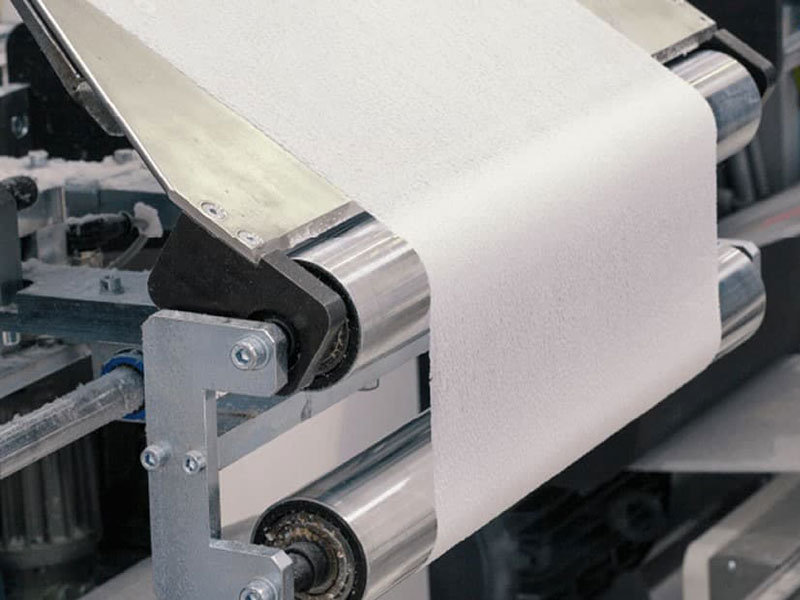

The non-woven fabric slitting machine is mainly used for cutting or slitting of wide rolls such as non-woven fabrics, and the non-woven fabric with the inner diameter of the paper tube is 75mm, the outer diameter of the non-woven fabric is 600mm, and the length is within 1600mm.

Functions of non woven fabric slitting machine:

1. Frame structure: whether it is a slitting or two or three slitting, domestic slitting machine manufacturers should invest energy, study the frame structure, and effectively design a more reasonable slitting machine from the perspective of slitting machine manufacturers, research and design a personalized slitting machine, so that the slitting of different materials in the structure is more detailed, in the next round of international market competition, to provide a favorable weapon for film enterprises, but also to find a blue ocean for their own enterprises.

2. Automation control part: At present, the automation level of the non-woven slitting machine produced in China is still at the middle and lower level, although the use of domestic control components has been very popular, and the price is low, but the domestic slitting machine manufacturers are far behind the level of foreign developed countries in the depth of use, especially in the control system and the structure of the slitting machine, and the lack of organic combination of the slitting materials, at this level, the vast majority of domestic slitting machines are still in the thick line, There is no deeper understanding of the rigor and rationality of the slitter control system. Domestic slitting machine manufacturers should start from the above directions to find a way that conforms to the principle of slitting machine control and slitting, and can use the functions provided by the hardware.

3. Manufacturing: This is a common problem faced by China's manufacturing industry, any mechanical equipment, in addition to the design is reasonable, in the manufacturing is also required, and China's manufacturing industry is lacking in this regard, in addition, the manufacturing process is also a weak link, manufacturing slitting equipment, in addition to some general machine tools, also need to have some special equipment for manufacturing slitting machines, such as dynamic balancing machines, water cutting machines, etc., because of the high precision requirements of slitting machines, so, some equipment needs to use CNC machine tools to process parts, In particular, it is necessary to popularize the use of machining centers, so that the processing accuracy of the equipment manufactured by the slitting machine can be fundamentally guaranteed

Features of non woven fabric slitting machine:

1. The power supply of the machine is three-phase four-wire system (AC380V) and grounded to ensure the safety of operators

2. Before powering on, the speed of the host should be adjusted to low speed first

3. Care should be taken when installing the blade to avoid scratches by the blade

4. The place where the machine needs to be refueled should be maintained regularly

Introduction of non-woven fabric slitting machine:

Non-woven fabric slitting machine is a kind of mechanical equipment that slits wide non-woven fabrics, paper, mica tape or film into multiple narrow materials, which is commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery.

The non-woven fabric slitting machine is mainly used in the slitting of non-woven fabrics, mica tape, paper, insulating materials and films, and is especially suitable for the slitting of narrow strips (non-woven fabrics, insulating materials, mica tapes, films, etc.).

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter