08. January, 2024delish0

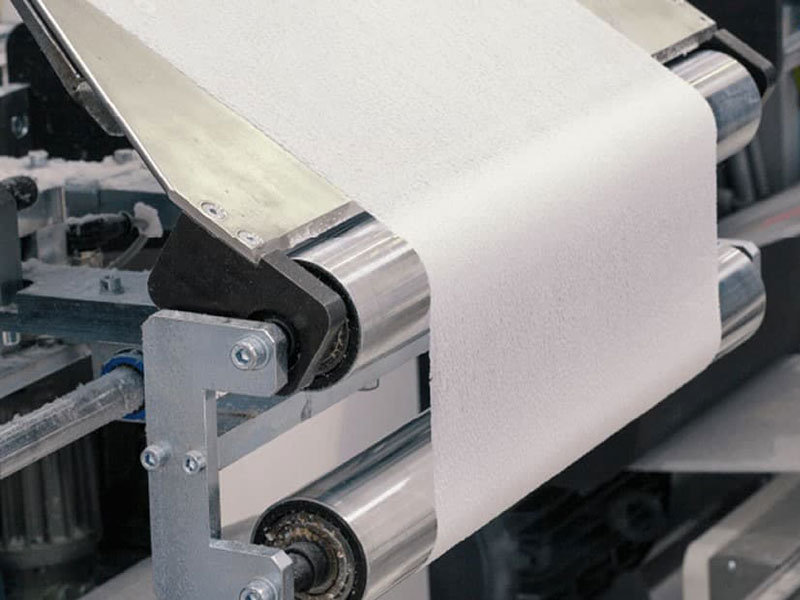

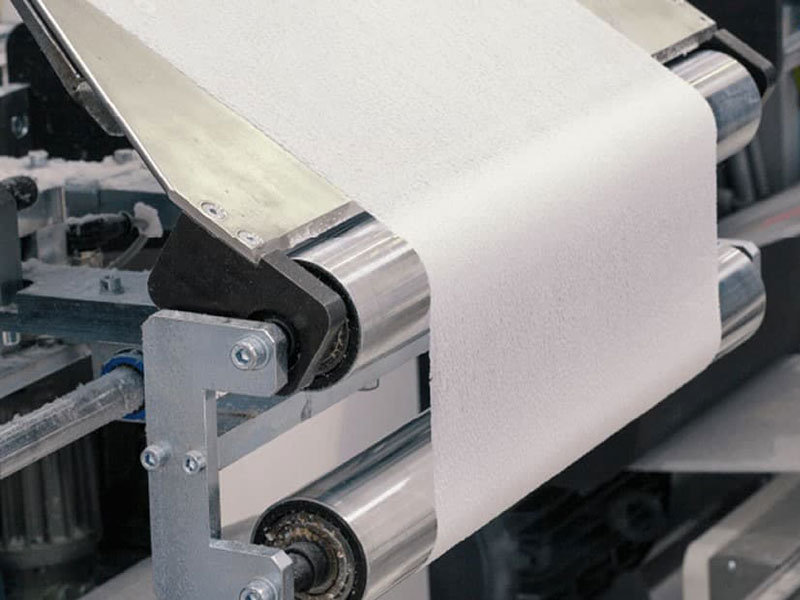

Non-woven fabric slitting machine is a kind of mechanical equipment that slits wide non-woven fabrics, paper, mica tape or film into multiple narrow materials, which is commonly used in papermaking machinery, wire and cable mica tape and printing and packaging machinery.

The non-woven fabric slitting machine is mainly used in the slitting of non-woven fabrics, mica tape, paper, insulating materials and films, and is especially suitable for the slitting of narrow strips (non-woven fabrics, insulating materials, mica tapes, films, etc.).

How to make better use of the non-woven slitting machine, it is necessary to understand the working principle of the non-woven slitting machine in detail, and only by understanding its internal structure can it be better used

1. The professional non-woven fabric slitting machine is a combination of center drive and surface drive, using high-precision frequency conversion speed regulation technology and arc-shaped synchronous belt drive, so that the slitting machine can achieve high winding accuracy and good stability.

2. The slitting machine of Foshan Shengtu adopts PLC centralized control, touch screen man-machine interface operation, and sets and displays working parameters according to the slitting requirements.

3. The raw material seat is pneumatic, photoelectric automatic tracking, and then controlled by PLC centrally.

4. The winding arm of the non-woven fabric slitting machine has an independent tension function, and the tension can be adjusted separately for films with uneven thickness or different widths.

Non-woven slitting machine "four maintenance requirements"

1. Neat: tools, workpieces, and accessories are placed neatly; Complete protective devices; The line pipeline is complete.

2. Qinggu: internal and external cleaning; Each sliding surface and lead screw, gear, rack, etc. are free of oil stains and no bumps; No oil leakage, no water leakage, no air leakage, no electricity leakage in all parts; Scrap garbage is swept away.

3. Lubrication: refuel and change the oil on time, and the oil quality meets the requirements; The oil pot, oil gun, oil cup, linoleum, and oil line are clean and complete, the oil mark is bright, and the oil path is smooth.

4. Safety: Implement the system of fixed personnel and machine and shift handover; Be familiar with the structure of the non-woven fabric slitting machine and abide by the operating procedures, use the non-woven fabric slitting machine reasonably, carefully maintain the tools, and prevent accidents.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter