15. January, 2024delish0

High-speed slitting machine because the mechanical operation is relatively fast when working, the efficiency will also be improved, for the high-speed slitting machine for many factories are to see its figure, especially for the processing of paper, the high-speed slitting machine can play a better effect, let's talk about the factors that affect the efficiency of the high-speed slitting machine?

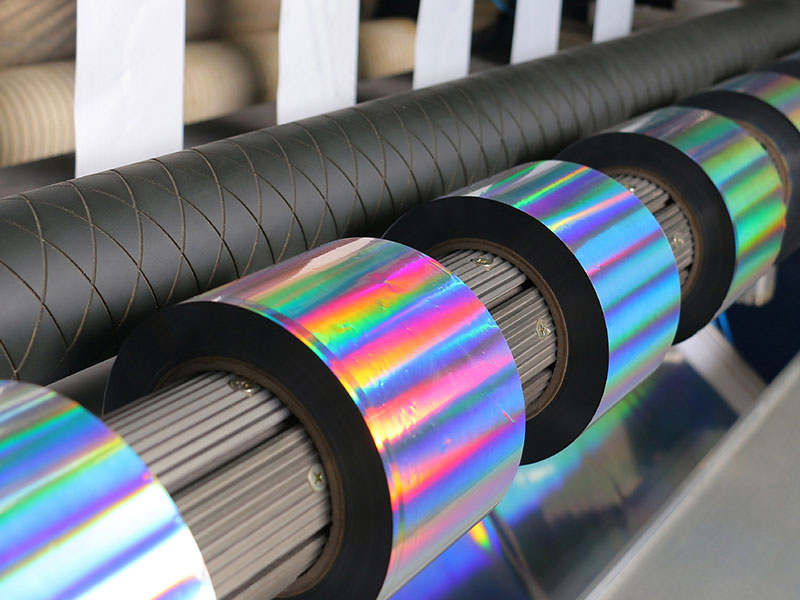

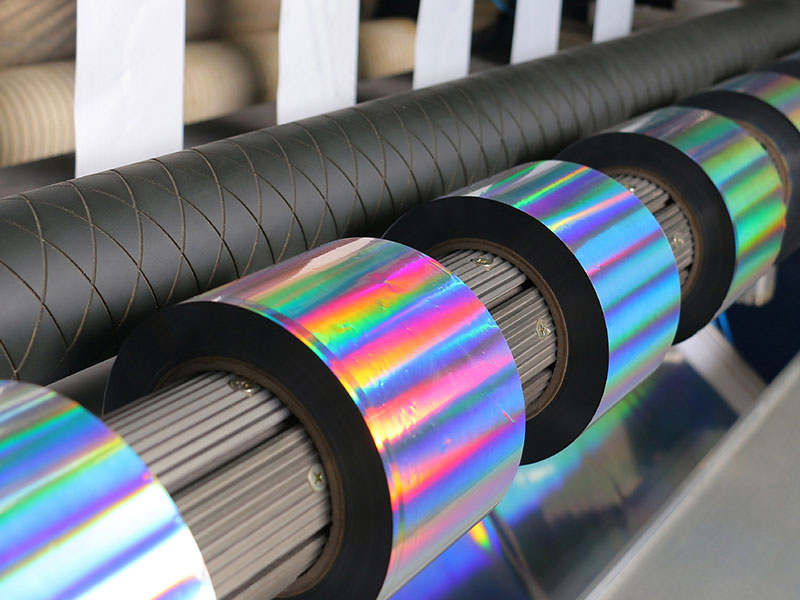

In the slitting process, the stable tension system is an important indicator to ensure product quality, which controls the mutual tension between unwinding, traction, slitting, rewinding, etc., so that the slitting material is always in a stable state in the slitting process. If the tension is properly controlled, the deformation and drift of the raw material in the process of increasing and decreasing the speed of the machine can be avoided. Generally, the unwinding tension is slightly greater than the sum of the winding shaft tensions.

In this way, if the non-operation occupies a long time, such as: machine adjustment, tool setting, tool change, material change, joint, roll change, processing problems and other long time, it is meaningless to simply improve the speed of the slitting machine. Not to mention the stability of the slitting machine, which will not only affect the working efficiency of the slitting machine, but also affect the product quality, and will cause trouble and unnecessary waste to the next process. So the working efficiency of the slitting machine is a comprehensive concept.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter