- Home

- About

- Product

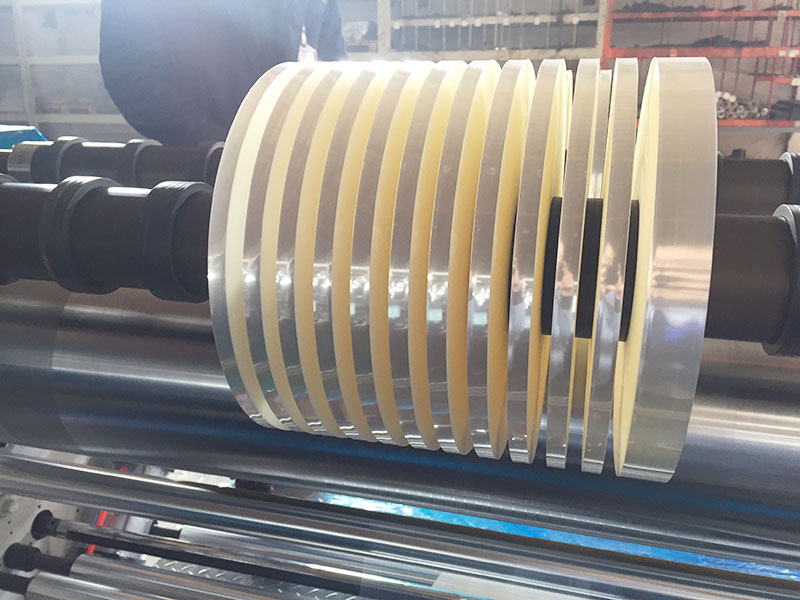

- TTR Slitter

- Foil Slitter

- Slitting Machine

- Copper Foil Slitting Machine

- BOPP Film Slitting Machine

- PVC film slitting machine

- Adhesive Label Slitting Machine

- Film Slitting Machine

- Paper Slitting Machine

- Slitting And Rewinding Machine

- Tape slitting machine

- Aluminum Foil Slitting Machine

- Correction Tape Slitting Machine

- Green Tape Slitting Machine

- Single-Sided Adhesive Tape Slitting Machine

- Foil Roll Cutter

- Mini Slitter

- Paper Core Cutter

- Paper Core Notch Cutter

- Paper Core Loading Machine

- Slitter Rewinder machine

- Barcode Ribbons

- Slitter Blade Holders

- Mask Making Machine

- Auto Packing Machine For TTR

- Hydraulic Hand Stacker

- News

- Application

- Support

- Contact

Search for anything.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter