12. April, 2024delish0

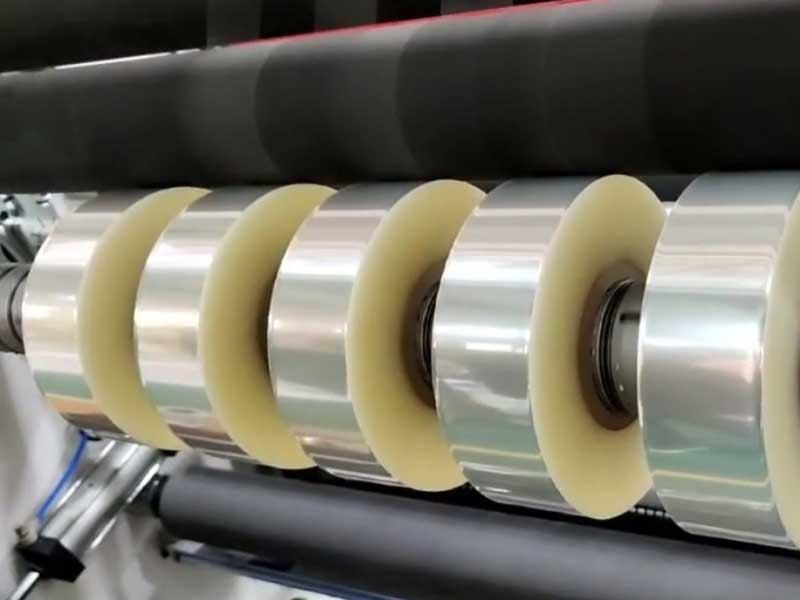

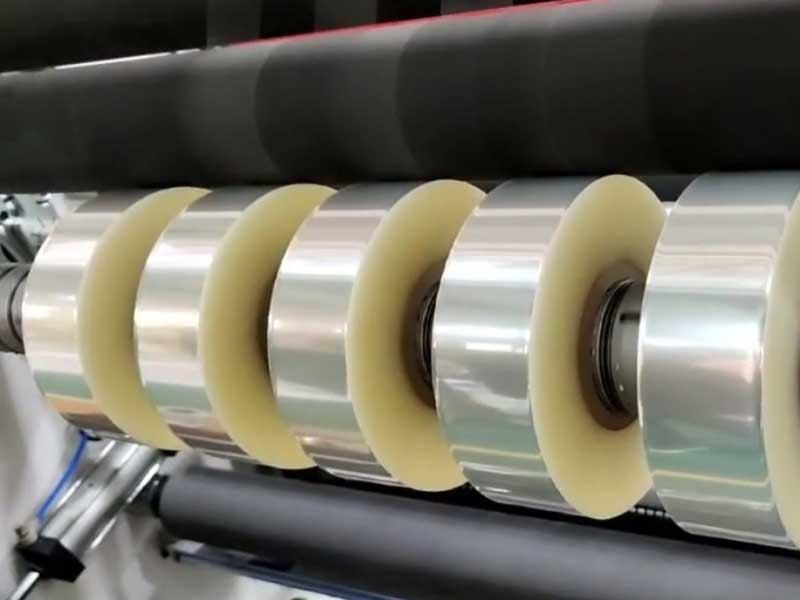

When the tension in the center of the slitting machine is too large or the pressure of the pressure roller is too large, when the surface is coiled, it will produce creases or creases on the surface of the film, which will affect the quality of the finished coil. Conversely, if the pressure/tension is reduced, the winding is too loose and can easily cause string problems. In particular, some large roller films, due to the uneven thickness at both ends, the pressure exerted by the same roller at both ends is unbalanced.

The engineers of the slitting machine manufacturer will use the best tension and pressure to eliminate the problem of uneven end face caused by the chord edge according to different types and specifications of the film, under the premise of ensuring the hardness of the film coil.

First of all, observe whether there is shaking on both sides of the roller when it rotates, which may be caused by bearing mounting problems, and observe whether there are gaps or unevenness. When the drum swings, the pressure at both ends of the membrane surface changes instantaneously, and the end with less pressure is easier to string. In addition, it is necessary to check whether the transmission parts are running well, whether the belt has teeth jumping or slipping, and whether the motor bearing rotates smoothly. As well as the relative curve of tension and velocity and diameter, there is no abruptness, and the problem is generally found through the timing of the string, and the corresponding fine-tuning is carried out.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Aluminum Foil Slitting Machine

Aluminum Foil Slitting Machine