13. April, 2024delish0

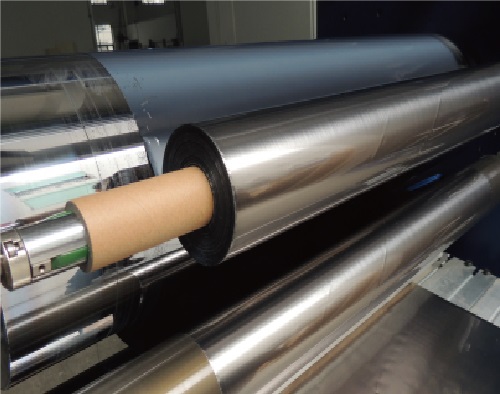

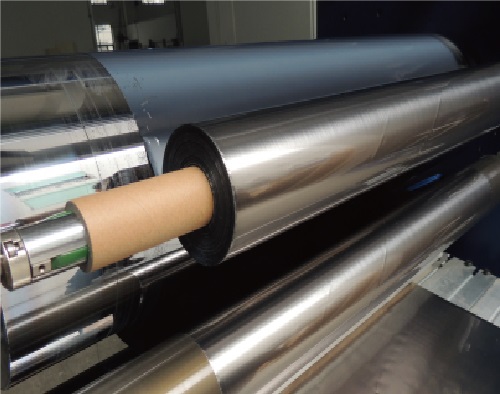

The center winding of the film slitting machine is also called active winding, the drum is usually driven by a motor, and the winding force is transmitted to the film substrate through the central shaft. In a center crimp system, the coil can be adjusted by the change in tension and pressure of the clamp. This type of slitter rewinding equipment can roll film at a lower winding tension and is gentle on the material.

The center winding method is ideal for plastic films or composites, thick plates, nonwovens and papers, which are sensitive to clamping force, as well as materials that are sensitive to tension or pressure in rewinding. However, the weight of the finished coil, the strength of the reel or core, and the maximum diameter of the film coil are still limited by the torque of the drive motor. Larger winding diameters require a larger core to accommodate larger reels, but also more powerful actuators, which place higher demands on overall power and installation space.

Generally speaking, the center crimp separator is difficult to avoid the influence of electrostatic adhesion on the air layer, and is suitable for low-speed, small-diameter winding. During the winding process, as the diameter increases, the tension also increases, which is easy to cause wrinkles near the paper core. At this time, the tension needs to be gradually reduced according to the taper calculation, and the deviation of the tension can be detected by the floating roller, and the signal is transmitted to the PLC, and the PLC will feed the calculated tension back to the inverter motor, and drive the central shaft to maintain the constant tension of the membrane. Of course, a magnetic powder brake can also be used to achieve constant tension by controlling the magnetic force on the winding device.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Aluminum Foil Slitting Machine

Aluminum Foil Slitting Machine