04. August, 2025delish0

By optimizing the cutting process and material utilization, the paper tube cutting machine can help enterprises save 30% of material costs, and the specific methods are as follows:

1. Precise cutting reduces waste

• High-precision control system: Using CNC or laser positioning technology, the cutting error can be controlled within ±0.5mm, avoiding material waste caused by the size deviation of traditional manual cutting.

• Intelligent nesting software: Algorithms automatically optimize the cutting scheme to maximize the use of tube material per roll (similar to sheet nesting technology) and reduce offcuts.

2. Automation reduces human loss

• Reduce operational errors: Automated cutting avoids manual measurement and marking errors, and reduces material loss caused by scrap cutting (about 5%-10% loss in traditional methods, and can be reduced to 1%-2% by automation).

• Continuous production mode: The automatic feeding and receiving system enables uninterrupted cutting, reducing material waste during downtime and material change.

3. Thin knife technology reduces incision loss

• Ultra-thin blade design: The blade thickness is reduced from the traditional 1.5mm to less than 0.3mm, reducing material loss by 1.2mm per tool. For high-frequency cutting scenarios (e.g. 10,000 cuts per day), the annual material savings can reach several tons.

• Debris-free cutting: Some models use ultrasonic or laser cutting, which produces almost no debris and improves material utilization by 3%-5%.

4. Dynamically adjust the pipe diameter and length

• Flexible adaptation to order needs: Quickly switch cutting parameters to support small-batch customized production and avoid waste caused by over-cutting to unified specifications.

• Reuse of Leftovers: The intelligent system records the size of the surplus and prioritizes the use of leftovers to complete small orders.

5. Data-driven optimization

• MES system integration: Real-time monitoring of material consumption, analysis of waste links (e.g. commissioning losses during equipment start-up) and reduction of overall usage through process improvements.

• Predictive maintenance: avoid cutting defects caused by tool wear (the defect rate can reach 8% after wear, and timely replacement can be controlled within 1%).

Cost saving case calculation

Assuming that the enterprise consumes 100 tons of paper tube raw materials per month, and the waste rate of the traditional method is 15% (15 tons waste), after adopting the optimization scheme:

• Precise cutting + nesting saves 7% → 7 tons

• Automation reduces errors by 3% → 3 tons

• Thin knife technology saves 2% → 2 tons

A total of 12 tons/month (12%) savings, combined with residual material management and long-term process optimization, can achieve comprehensive savings of up to 30%.

Implementation recommendations

• Select the adaptation model: match the equipment according to the pipe diameter (such as 20-300mm), hardness and other parameters.

• Employee training: standardize the operation process (e.g. correct setting of cutting parameters) to maximize the effectiveness of the equipment.

• Regular Maintenance: Maintain tool sharpness and avoid hidden waste.

Through technological upgrades and process optimization, paper tube cutting machines can reduce material costs from multiple dimensions, especially suitable for enterprises with large quantities or high-precision needs.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

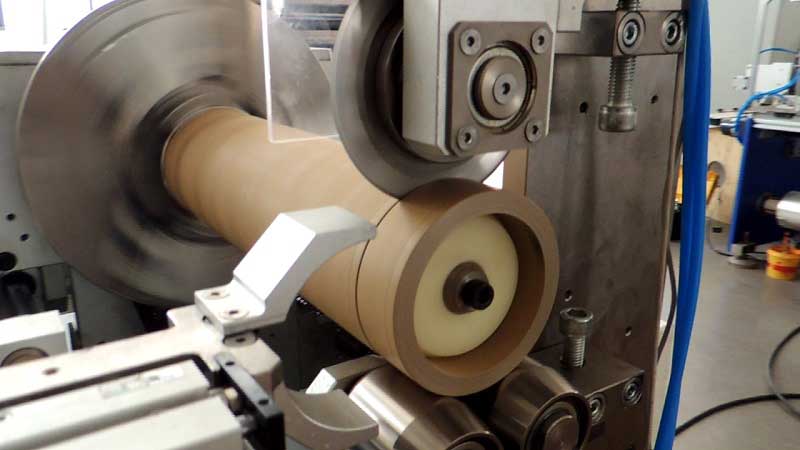

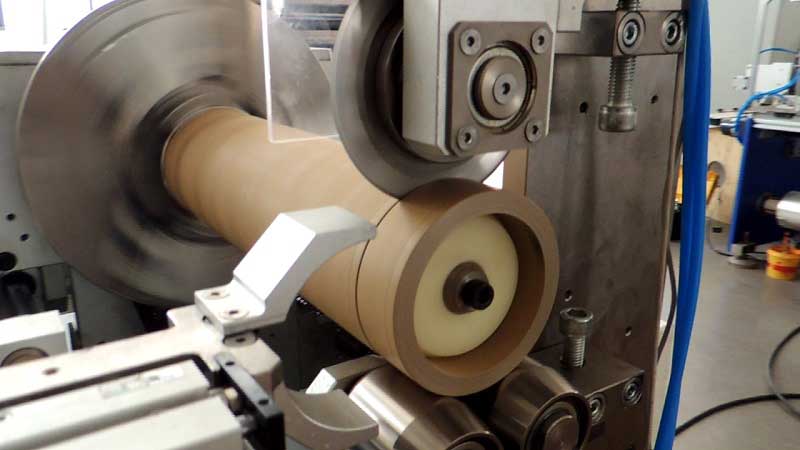

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter