09. August, 2025delish0

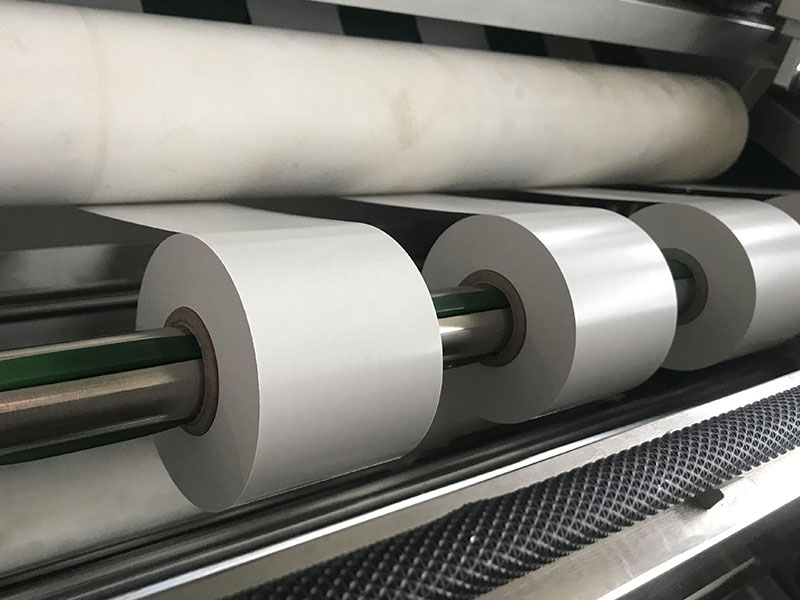

Single-sided adhesive slitting machines play an important role in modern industrial production, and their precision slitting technology has brought significant benefits to the manufacturing industry, mainly reflected in the following aspects:

The core advantages of precise slitting

1. Maximize material utilization

◦ Millimeter-level slitting accuracy is achieved through high-precision control system

◦ Reduces edge waste from traditional cutting methods

◦ Optimize the nesting scheme to maximize the use of raw materials

2. Reduce production waste

◦ Automatic deviation correction system avoids material loss due to cutting errors

◦ Digital control eliminates human error

◦ 30-50% less scrap than traditional methods

3. Economic benefits are improved

◦ Reduce the cost of raw material procurement

◦ Reduced waste disposal costs

◦ Improve product consistency and reduce defect rates

Principle of technical implementation

Single-sided adhesive slitting machines achieve precise slitting through the following technologies:

• High precision servo control system

• Laser or vision positioning system

• Real-time tension control

• Intelligent nesting algorithm

This precision slitting technology is particularly suitable for high-demand slitting applications for tapes, films, and other materials in electronics, medical, packaging, and other industries, providing a reliable solution for enterprises to reduce costs and increase efficiency.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter