14. August, 2025delish0

To ensure that each roll of tape produced by the single-sided rubber slitting machine is evenly slitted and burr-free, it needs to be controlled from various aspects such as equipment adjustment, material selection, process parameter optimization, and operation specifications. Here are the specific measures:

1. Equipment inspection and maintenance

• Tool Status:

◦ Use high-precision round or flat knives to ensure sharp and notch-free blades. Regularly inspect and replace wear tools (mandatory replacement is recommended after each length of production).

◦ The tool should be installed firmly to avoid shaking during operation, and the radial runout of the tool shaft should be less than 0.02mm.

• Slitting Machine Calibration:

◦ Adjust the parallelism and concentricity of the tool to ensure that the gap between the upper and lower or opposite tools is uniform (usually 10%~20% of the material thickness).

◦ Check the rewinding tension control system to ensure stable tension (adjustable by tension sensor or magnetic particle brake).

• Cleaning and maintenance:

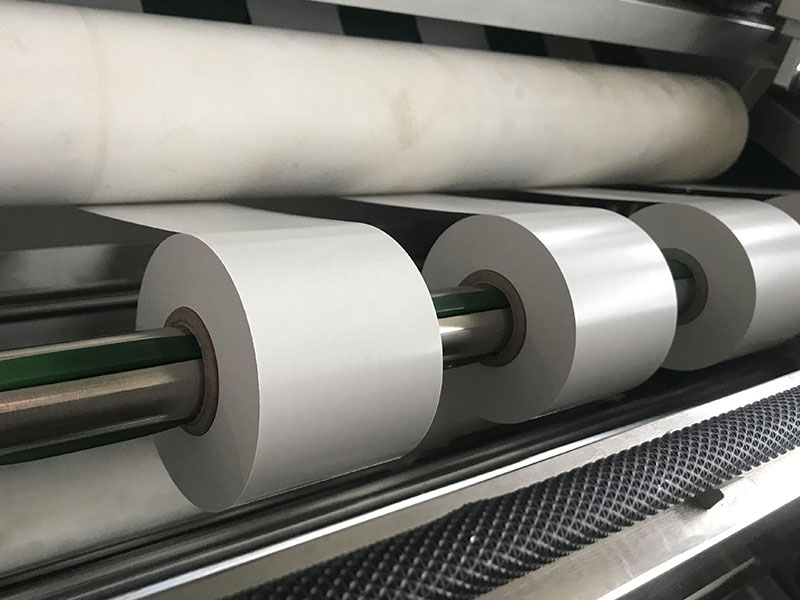

◦ Timely clean up glue stains and debris on the knife surface and guide rollers to prevent impurities from affecting the slitting effect.

2. Material control

• Substrate quality:

◦ Select the original tape roll (such as PET, BOPP, etc.) with uniform thickness, no impurities, and neat edges to avoid slitting problems caused by raw material defects.

◦ The storage environment should be moisture-proof and dust-proof to avoid adhesive aging or substrate deformation.

• Unwinding Alignment:

◦ Use an automatic deviation correction device (EPC system) to ensure that the original coil does not have lateral offset when entering the slitting machine.

3. Optimization of process parameters

• Slitting speed:

◦ Adjust the slitting speed according to the material properties. Thicker or high-viscosity tapes need to be slitted at low speed (such as 30~50m/min), and thin materials can be appropriately accelerated.

• Tension control:

◦ The unwinding, slitting, and winding tension should be adjusted in sections to avoid over-tightness (causing the tape to stretch and deform) or over-loosening (causing the coil to loosen).

◦ It is recommended to use taper control for winding tension, and gradually decrease the tension with the increase of coil diameter (such as initial tension 5N, taper 10%).

• Temperature and humidity:

◦ The ambient temperature is recommended to be controlled at 20~25°C and the humidity is 40%~60% to prevent the change of tape viscosity or the shrinkage of the substrate.

4. Slitting process adjustment

• Tool Matching:

◦ Select the tool type according to the thickness of the tape. Thin tape (<0.05mm) can be slitted with a single knife, and thick tape needs to be cut with a double knife or a circular knife.

◦ The recommended tool angle is 20°~30° to reduce cutting resistance.

• Slitting width control:

◦ The tool holder is driven by a high-precision servo motor to ensure that the slitting width error ≤± 0.1mm.

◦ Regularly use calipers to spot check the width of the slitted tape.

• Burr Treatment:

◦ Add an electrostatic eliminator to reduce electrostatic adsorption debris generated during slitting.

◦ For high-demand products, a brush or a vacuum cleaner can be added to clean the edges.

5. Operation and quality inspection

• Operating Specifications:

◦ Before starting the machine, idle and try to cut to confirm that the equipment is running smoothly.

◦ The first roll of products needs to be fully inspected (width, edge, stickiness), and mass-produced after qualification.

• Real-time monitoring:

◦ Install CCD visual inspection system or laser width gauge to automatically identify slitting defects and alarm.

• Post-processing:

◦ After slitting, the tape should be left for 24 hours before packaging to release internal stress and avoid core deformation.

Frequently Asked Questions and Countermeasures

• Burrs: Check for tool wear or excessive clearance to reduce slitting speed.

• Coil wrinkling: adjust the winding tension and check the parallelism of the guide rollers.

• Tape adhesion: Apply silicone oil release agent before slitting, or replace the low-tack backing paper.

With the above combined control, the slitting uniformity and edge quality can be significantly improved. For high-end applications (e.g. tapes in the electronics industry), fully automatic slitting machines with high-precision servo systems and in-line inspection are recommended.

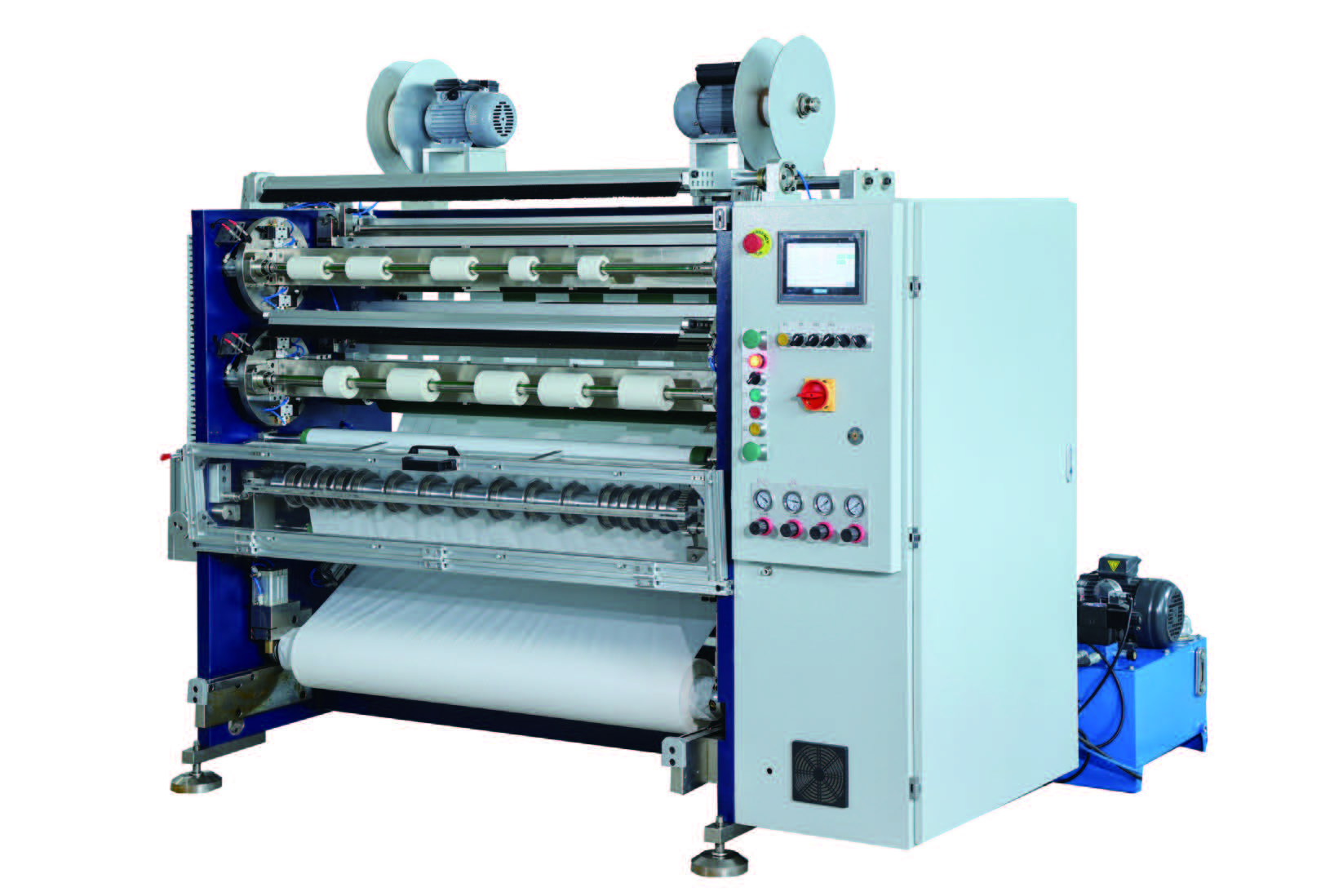

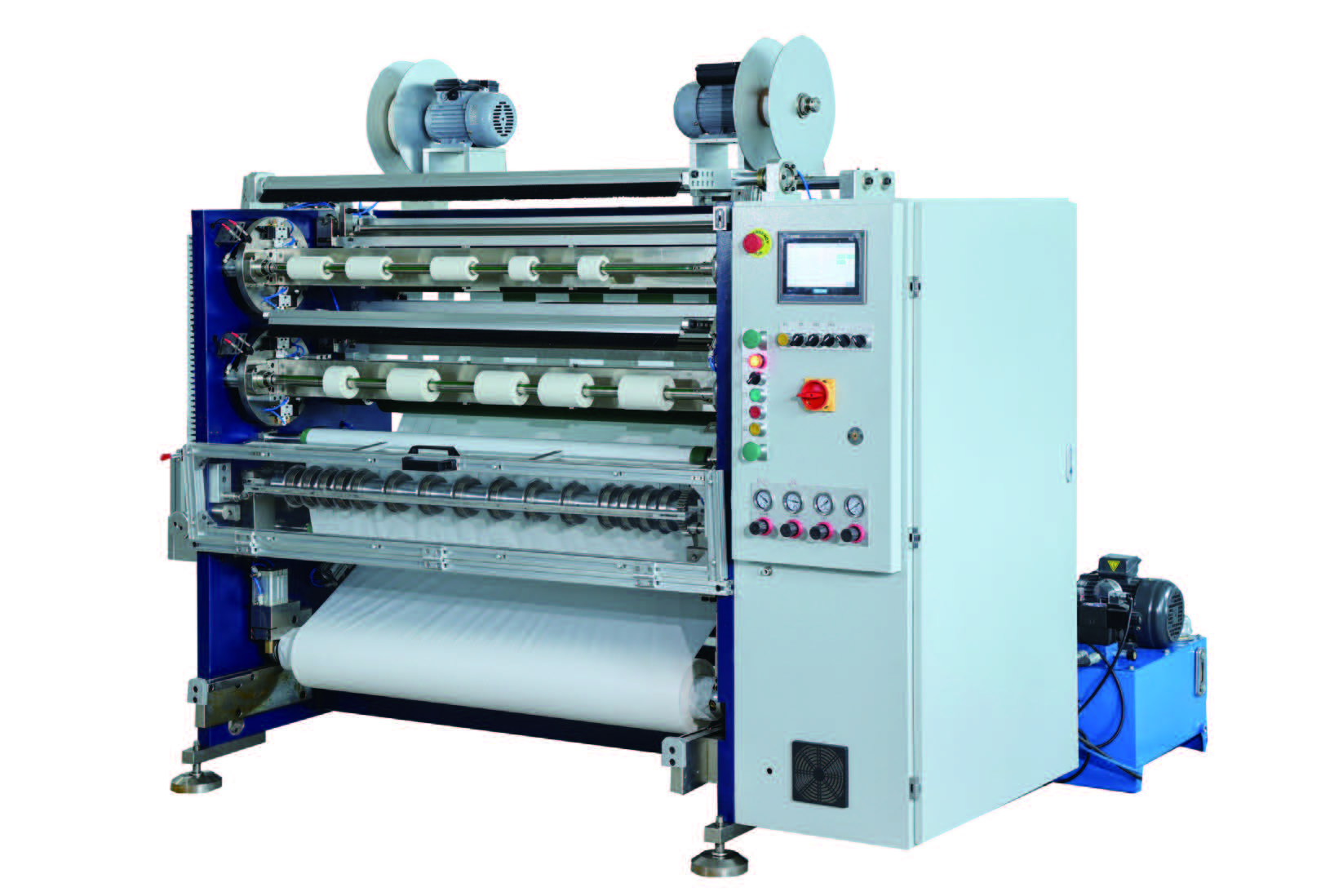

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter