18. October, 2025delish0

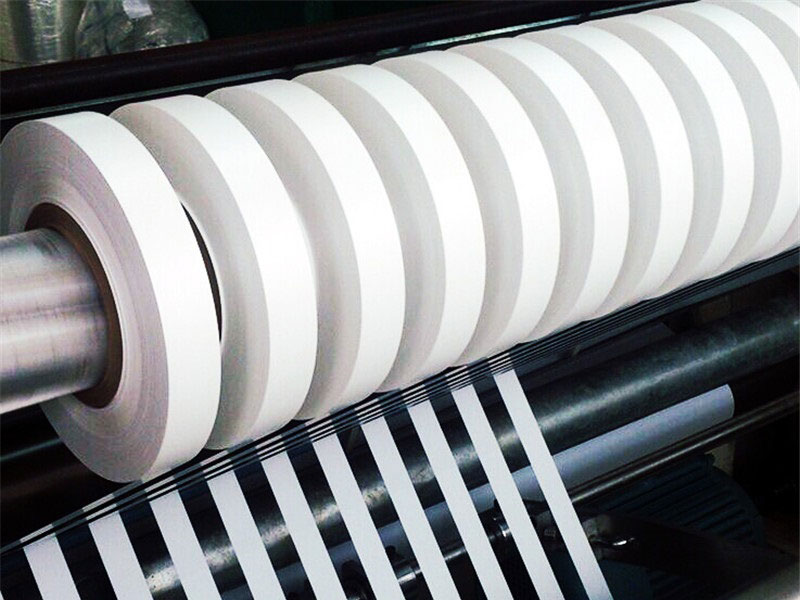

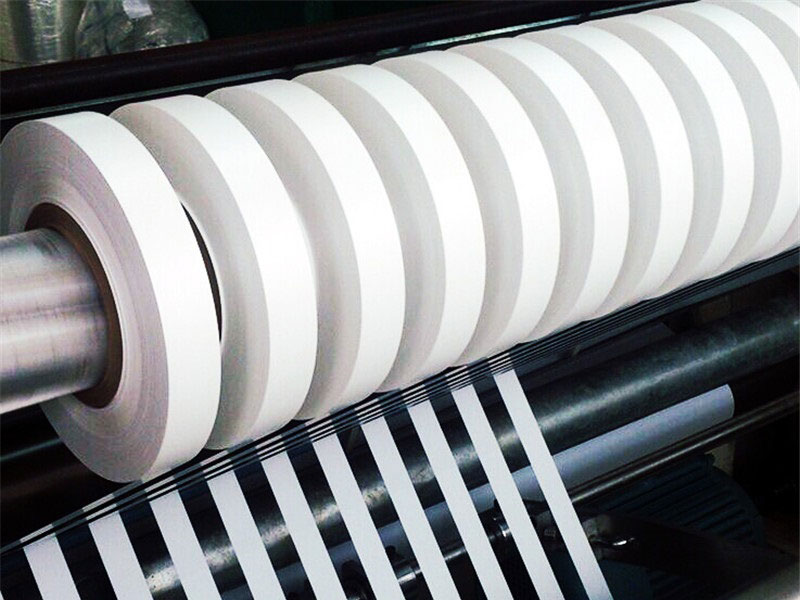

Behind the scenes of industry and everyday life, tape plays an indispensable role as a "gluer". From sealing tape to protect express packages, to thin tape for precision electronic components, to masking tape in creative workshops, they all silently maintain the operation of the world in different widths and shapes. However, at the heart of the process of transforming huge master rolls into a dazzling array of small finished rolls, the tape slitting machine, always faces an inherent challenge: how to gracefully navigate the "stickiness" itself.

The dilemma of slitting caused by "stickiness"

Adhesiveness is the soul of tape, but it is also the most difficult problem in the slitting process. Under the high-speed rotating cutter wheel, the tape is precisely split in two, but sticky like a pair of invisible hands trying to re-aggregate everything.

• Glue residue and adhesion: At the moment of slitting, the adhesive on the surface of the rubber surface that is cut off may adhere to the blade, just like syrup sticks to a spoon. This will not only contaminate subsequent products, lead to "drawing" and "overflow" of the tape edges, but also quickly passivate the blade, increase the frequency of downtime cleaning and replacement, and seriously affect production efficiency.

• Uneven winding and "burst ribs": When rewinding the narrow strips of tape after slitting, it will not be able to be wound perfectly in parallel due to uneven tension or edge stickiness interference. at best, the winding end face is uneven, which affects the aesthetics; At worst, it forms raised "violent tendons", making it difficult for the tape to be pulled out smoothly during use, and even collapsing and deforming during transportation, becoming a waste product.

• Static Dust Absorption: High-speed slitting friction generates a large amount of static electricity, making the surface of the tape a "vacuum cleaner". Tiny dust and impurities are firmly adsorbed on the rubber surface, which is undoubtedly a fatal flaw for applications with extremely high cleanliness requirements, such as medical and electronics.

These problems, like a gully between quality and efficiency, test the wisdom and skill of each slitting machine.

Neat solution: precise cutting of technology and wisdom

In the face of the challenge of stickiness, modern tape slitting machines do not fight brutely, but use a series of exquisite innovations and technologies to achieve an elegant turn of "neat solution".

1. The innovation of "cold weapons": special slitting knives

For glue residue, material and process are key. Blades with Teflon, ceramic or diamond coating have a very low and smooth surface that effectively prevents adhesive adhesion and keeps the blade clean and sharp for a long time. At the same time, the shearing mode of precise cooperation between the circular knife slitting and the bottom knife is like scissors, achieving clean instant cutting instead of squeezing tearing, reducing the possibility of glue being "dragged" out from the source.

2. Control of the "Invisible Hand": High-precision tension control system

Whether the winding is flat or not, the core lies in the control of tension. Modern slitting machines are equipped with a fully automatic tension control system, which monitors the tightness of the material belt in real time through sensors and automatically adjusts the torque of the winding motor. From the slitting point to the rewinding reel, the tension is always like an invisible silk thread, which is precisely controlled in the best state, ensuring that each layer of tape is tightly and parallel, eliminating "burst tendons" and looseness.

3. Guardian of "Clean Guard": Static Removal and Dust Removal Device

In order to solve the problem of electrostatic vacuuming, the slitting machine is equipped with ion air rods or electrostatic brushes at key positions, which can generate a large number of positive and negative ions to neutralize the electrostatic charge on the material belt, so that it can no longer absorb dust. With the vacuum dust removal device, the surface of the tape is purged or adsorbed before and after slitting to ensure that the finished tape is as smooth as new.

4. The leadership of the "smart brain": automation and intelligence

Modern slitting machines have evolved into an intelligent platform. Through PLC (Programmable Logic Controller) and HMI, the operator can preset all the parameters required for different tape materials and widths – tension, speed, pressure. The machine can automatically complete slitting, roll change, labeling, and even detect defects online. Intelligence allows the process of solving sticky problems to change from relying on the experience of masters to stable and replicable precision science.

Conclusion: See the true chapter in the subtleties

The tape slitting machine, a seemingly simple industrial equipment, is actually a precision stage that cleverly deals with physical properties in the microscopic world. It transforms the love-hate "stickiness" of tape into a neat, high-quality finished product through the light of technology.

"Sticky problems, neat solutions" - these eight words are not only a functional description of an efficient equipment, but also an interpretation of the modern industrial spirit: with continuous innovation and ultimate precision, the most difficult challenges are turned into the smoothest processes. When we easily tore off a piece of tape, it was this precision system behind it that completed that clean "cut" for us.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Aluminum Foil Slitting Machine

Aluminum Foil Slitting Machine