24. November, 2023delish0

In order to stabilize the quality of the slitting machine product and ensure the pass rate of the product, it is stipulated as follows:

1. Incoming inspection: according to the quality of the incoming materials, wall thickness, and the number of broken ends, the plan should be reasonably arranged, and the main operator should consider digesting the broken ends as much as possible to reduce the joint rate under the condition of ensuring that the volume diameter and meters required by the customer are met. If the material with too many incoming broken ends and too many airways does not meet the requirements of foreign trade orders, priority should be given to the small shaft plan with some indefinite length. (Foreign trade orders generally require no joints or only one street is allowed, and the joint rate is within 20%)).

2. Bottom thickness: The reasons for the bottom thickness are: (1) The core is unqualified: the core wall thickness is different, the surface quality is poor and uneven, and the qualified core should be replaced. (2) Poor incoming plate type: the incoming plate type is tight and loose on the loose side of the plate type when coiling, and the bar will be wrinkled, flicking, and the three plate rollers at the entrance should be adjusted to adjust the plate type, and the tension and pressure should be adjusted appropriately. (3) Improper setting of process parameters: there are errors in setting parameters: such as incoming width, thickness, dynamic compensation, tension gradient, pressure, tension, etc., further adjustment should be made according to the situation. (4) Machine problems: large runout of the winding shaft, large or small winding measurement, asynchronous rubber roller, electrical failure, etc., find an electric fitter to deal with it in time.

3. Slash and soft bar: The uneven lines on the surface of the aluminum coil are called slashes and soft bars in the form of straight lines and oblique lines, which often occur in the slitting process. (1) Excessive coiling tension will also cause soft bars, and the coiling tension should be appropriate and not too large during operation. (2) Improper adjustment of the pressure at both ends of the flattening roller and the support roller will also cause soft bars and slashes, and the pressure should not be greatly adjusted in the normal operation of the machine. (3) The unstable operation of the equipment, such as: the machine speed is too fast, the winding shaft runs, the rubber roller is out of sync, etc., which will cause the soft bar and slash to find an electric fitter in time to deal with it.

4. Welding: (1) Wrinkling of the weld layer after welding operation: if the belt is broken during the slitting process, it needs to be welded, and the small coil of each shaft should be evenly picked. After the incoming material is broken and stopped, it is necessary to remove the number of meters generated after parking (because the tension may be too large during the parking process, resulting in the coil layer). Run as much as possible 100-3 meters after running at low speed with the belt, so as to avoid the string layer caused by the welding bar caused by the plate type not being straightened, the aluminum foil on the welding roller should be supplemented by flattening, and the upper and lower layers of anhydrous ethanol should be wiped to fix the aluminum foil, and the head should be aligned. After welding, the running tension should be appropriate, and too large or too small tension will also cause wrinkled strings (2), and the welding is not firm: the tearing edge should be smooth, and there should be no burrs, forks, residual edges, etc. The aluminum foil overlap should not exceed 3mm, and there should be no bulging, bubbles, and wrinkles at the lap to prevent defects (damage, false welding, etc.) on the weld. (3) Alcohol spots: When welding, in order to prevent aluminum from sticking to ensure the quality of welding, the disc must be moistened with alcohol or the aluminum foil should be wetted, and the amount of alcohol should not be too much, so as to attach to the aluminum coil and cause annealed macula.

5. Unloading into the frame: in the unloading into the frame, there will be some quality conditions such as end face collision, abrasion, dirty end face, surface crushing, etc., in the process of unloading into the frame, the end face must be protected with foam pads, and the materials on the ground must be protected with a good end face, and the materials placed on the ground must be cushioned with felt or foam, and the surface is not allowed to produce obvious pitting, in addition, it is not allowed to put the material on the aisle.

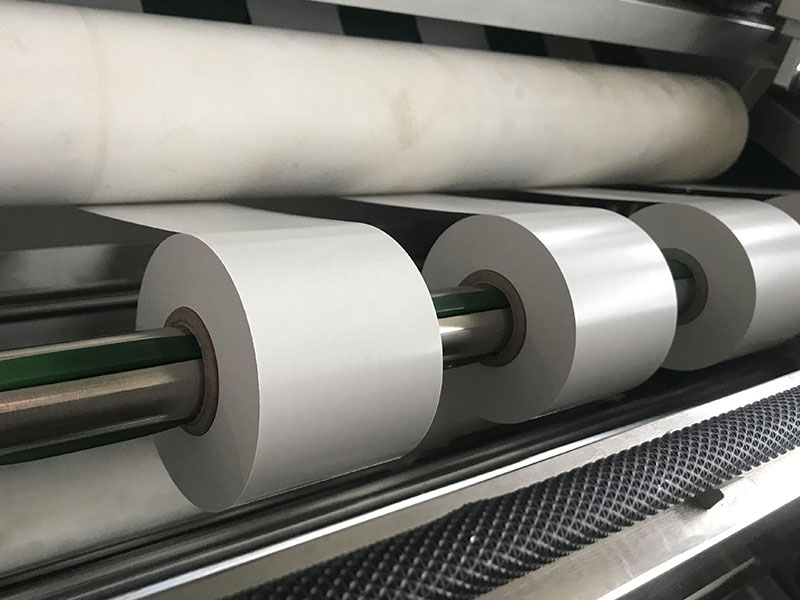

Fully Automatic TTR Slitter RSDS8 Plus

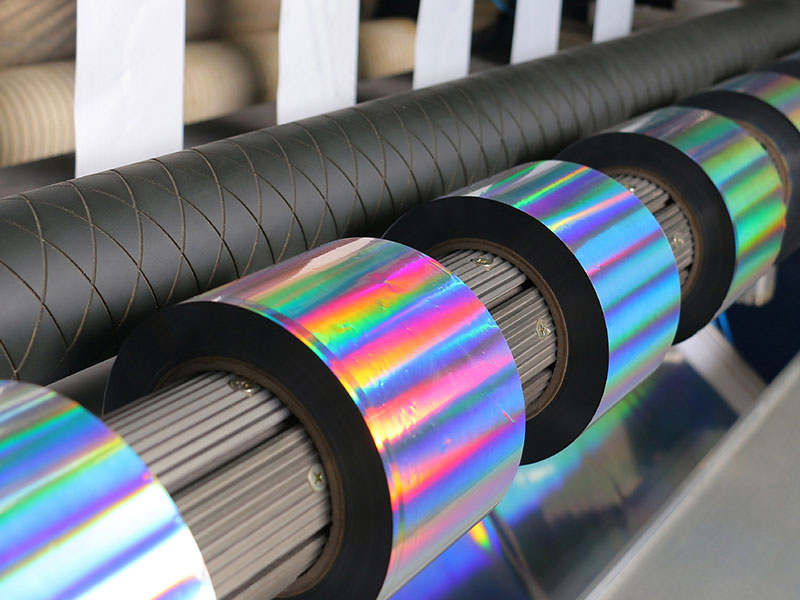

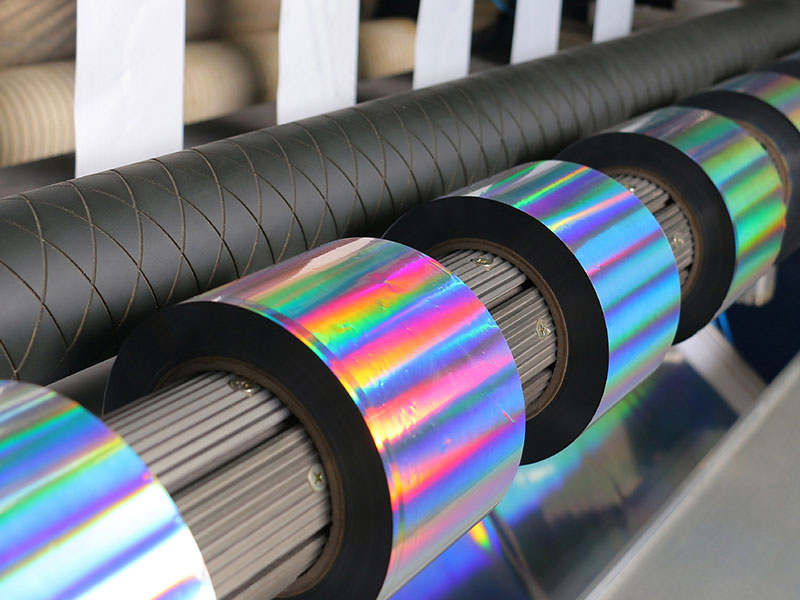

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Aluminum Foil Slitting Machine

Aluminum Foil Slitting Machine