23. November, 2023delish0

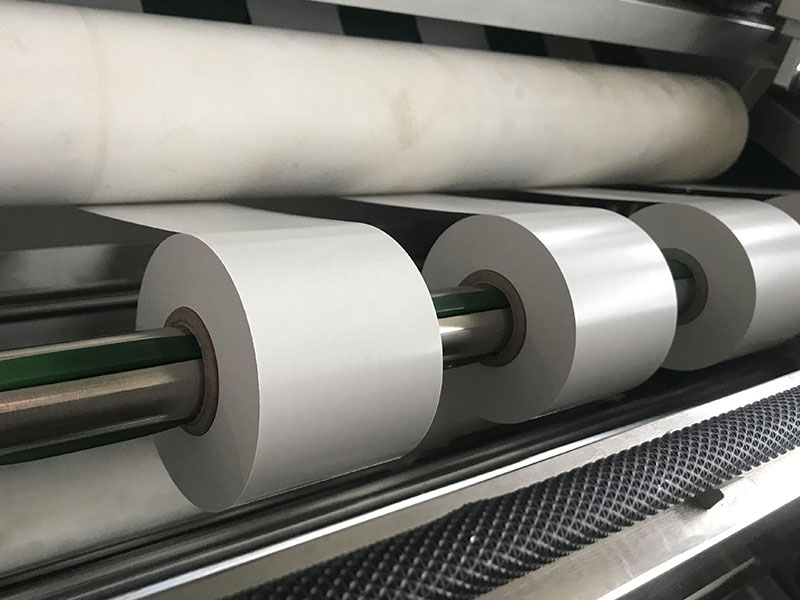

Slitting machine in film, printing, paper and label industries, is an inseparable processing equipment link, slitting machine application industry is different, process requirements are different, the requirements for slitting machine are also different. But for the overall architecture of the slitting machine, it is the same, and everything changes.

There are several main structural forms of slitting machine

We classify from the conventional film slitting machine, generally there are four forms, double-shaft center winding and slitting machine, double-shaft surface winding and slitting machine, gantry station winding and slitting machine, gantry center surface winding and slitting machine. These slitting machines in the form of structure are produced by Lipu Machinery, especially in the previous three applications. The structure and function of these forms of slitting machines before winding are not much different, and the main difference is that the winding part of the slitting machine is different.

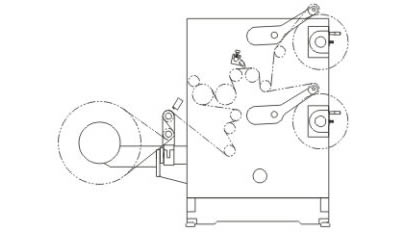

1.Double-shaft center winding and slitting machine

The two winding shafts are each driven by a motor, or the two winding shafts are driven by a motor, and the winding force of the slitting material is transmitted by the motor to the belt, the rewinding shaft, the paper core, and the slitting material in turn.

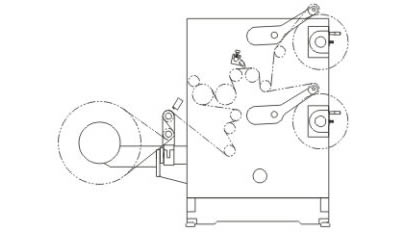

2.Double-shaft surface winding and slitting machine

Twin shaft surface winding and slitter, also known as back-to-back slitting machine, two non-powered driven winding shafts, leaning on the same main drive roller, through the contact between the surface of the winding material and the surface of the main drive roller, the winding force is obtained. The winding force is successively transmitted by the motor to the belt, the main drive roller, the winding material, the paper core, and the winding shaft.

The double-shaft surface winding and slitting machine was later derived from the double-shaft central surface winding and slitting machine, which is based on the original slitting machine, adding two winding motors to drive two winding shafts respectively.

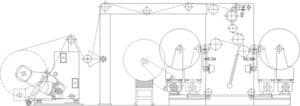

3.Gantry station type winding and slitting machine

The slitting machine with gantry structure is suitable for manufacturers of raw film substrates, such as the production of CPP, BOPP, BOPET and other materials, the width of the raw materials to be slitted is more than 2 meters, and the diameter of the unwinding and winding materials is more than 800mm.

Due to the large width and diameter of the winding material, each winding material is rewinding by a winding workstation, each winding station has a set of independent winding drives, and the air path and control system that cooperate with each independent winding station.

Its transmission mode is the same as that of the double-shaft winding and slitting machine, and the winding force of the slitting material is successively transmitted by the motor to the belt, the winding chuck, the paper core, and the slitting material.

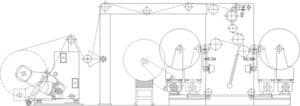

4.Gantry center surface winding and slitting machine

Gantry center surface winding and slitting machine is a combination of independent winding workstation and center surface winding and slitting, due to few applications, it is not highlighted here.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Aluminum Foil Slitting Machine

Aluminum Foil Slitting Machine